Explore Our Product Range

With an up-to-date stock, BDA has a wide range of products to offer to different industrial segments. Our products are acquired by Lost Wax Precision Investment Casting, Sand Casting, C.I. & S. G. Iron Foundries, Steel Plants, Ceramics & Refractory Industry, Textile Dyeing & Printing, Foundry Mould Paint, Other Paint Industries and more. BDA products range is a diversified collection of Minerals, Chemicals, Waxes, Refractories, Insulation Materials & Technology Ceramics. Here is a listing of the products, segment wise.

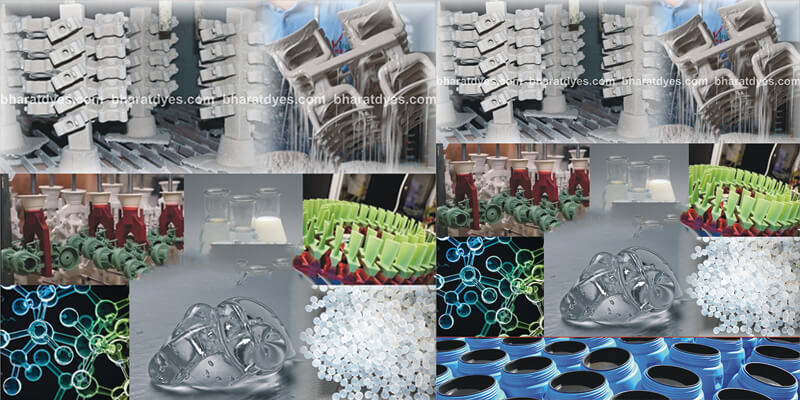

Mined and processed from best natural sources or synthetically processed, our range of minerals CALUSIL® are available as per standards & customized requirements. Our minerals are processed in latest machines considering and following the safety precautions. In addition to the minerals division BDA supplies processed and natural prime quality zircons as ZIRCOPRIME®. BDA minerals are procured in an extremely wide range of industrial and many other applications.

Metals works at its best when the right refractories are used. Our refractories safeguard the furnace from direct contact with molten metal plus deliver better lining life with slightest inclusions to obtain the surface quality of the final casting product. BDA offers a wide range of refractory materials which are highly effective. The usage of these refractories impacts various areas & it helps in reducing the energy cost, lesser expense on repair and maintenance for safety lining and overall reduction in the cost of production for foundries & steel plants.

BDA insulation materials include high quality insulators which are competent in protection of the machinery or different objects. These materials work by reducing thermal conduction or reflecting the thermal radiation instead of absorbing it.

Our cores are made from materials that have very low coefficients of thermal expansion, an extremely desirable property for investment casting & are also easy to leech out through chemical reactions. These ceramic cores are sacrificial ceramic structures primarily used for forming cavities that are too complex to be machined within investing casting procedures.

With an upper hand in chemical manufacturing & processing under our own brand PRECIBOND® we have a comprehensive range of industrial chemicals which includes polymers, solvents, binders, release agents, wetting agents, antifoams & finishing chemicals. Our chemicals come up with superior performance, excellent bonding & compound stability. They are developed to perform more tolerant of unfavourable environmental conditions (humidity, temperature, air movement).

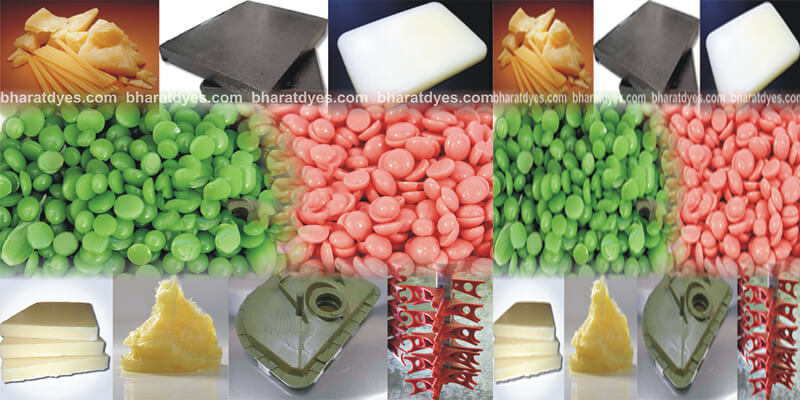

Pattern waxes play a vital role in the process of investment casting process. Investment casting wax compounds are complex, consisting of different blends and consequently exhibit a range of properties. The wax properties influence pattern behaviour in the foundry and ultimately the quality of castings produced. To fulfil these requirements, BDA have accumulated a wide range of DURACAST® waxes with controlled flow property, dimensional consistency, surface finish & recyclable properties.